Serpentine belt replacement is a crucial maintenance task that every vehicle owner should be aware of. The serpentine belt plays a vital role in the operation of various engine components, including the alternator, power steering pump, water pump, and air conditioning compressor. Understanding how to replace this belt can save you time and money and ensure your vehicle runs smoothly. In this article, we will explore everything you need to know about serpentine belt replacement, including signs of wear, the replacement process, and tips for maintenance.

Whether you're a seasoned mechanic or a first-time DIYer, this guide will provide you with detailed information on serpentine belt replacement. We'll cover the tools needed, the step-by-step process, and the common mistakes to avoid. With proper knowledge and preparation, you can confidently tackle this important automotive task.

In addition to the practical aspects of serpentine belt replacement, we'll also discuss the importance of regular maintenance and the potential consequences of neglecting this task. By the end of this article, you'll have a comprehensive understanding of serpentine belts, their function, and how to replace them effectively.

Table of Contents

- What is a Serpentine Belt?

- Importance of the Serpentine Belt

- Signs of Wear and Tear

- Tools Needed for Replacement

- Step-by-Step Serpentine Belt Replacement

- Common Mistakes to Avoid

- Maintenance Tips for Serpentine Belts

- Conclusion

What is a Serpentine Belt?

The serpentine belt is a long, winding belt made of durable rubber that connects various components of the engine. Unlike older vehicles that use multiple belts for different components, modern vehicles typically use a single serpentine belt to drive multiple accessories. This design reduces weight, enhances efficiency, and minimizes the complexity of the engine compartment.

Importance of the Serpentine Belt

The serpentine belt is essential for the proper functioning of various engine components, including:

- Alternator

- Power steering pump

- Water pump

- Air conditioning compressor

If the serpentine belt fails, it can lead to a loss of power steering, overheating of the engine, and a dead battery. Therefore, regular inspection and replacement of the serpentine belt are vital for maintaining the overall health of your vehicle.

Signs of Wear and Tear

It's important to recognize the signs that indicate your serpentine belt may need replacement. Some common signs of wear and tear include:

- Cracks or fraying on the belt surface

- High-pitched squealing noises

- Loss of power steering assistance

- Overheating engine

- Warning lights on the dashboard

If you notice any of these symptoms, it's crucial to inspect the serpentine belt and consider replacement as soon as possible.

Tools Needed for Replacement

Before you begin the serpentine belt replacement process, gather the following tools:

- Socket set

- Ratchet and extensions

- Torque wrench

- Belt tensioner tool (if required)

- New serpentine belt

- Safety gloves and goggles

Step-by-Step Serpentine Belt Replacement

Follow these steps to replace your serpentine belt effectively:

1. Prepare the Vehicle

Park your vehicle on a flat surface, turn off the engine, and engage the parking brake. Allow the engine to cool if it was recently running.

2. Locate the Serpentine Belt Diagram

Before removing the old belt, locate the serpentine belt routing diagram. This diagram is usually found on a sticker near the engine or in the vehicle's manual.

3. Release Tension on the Belt

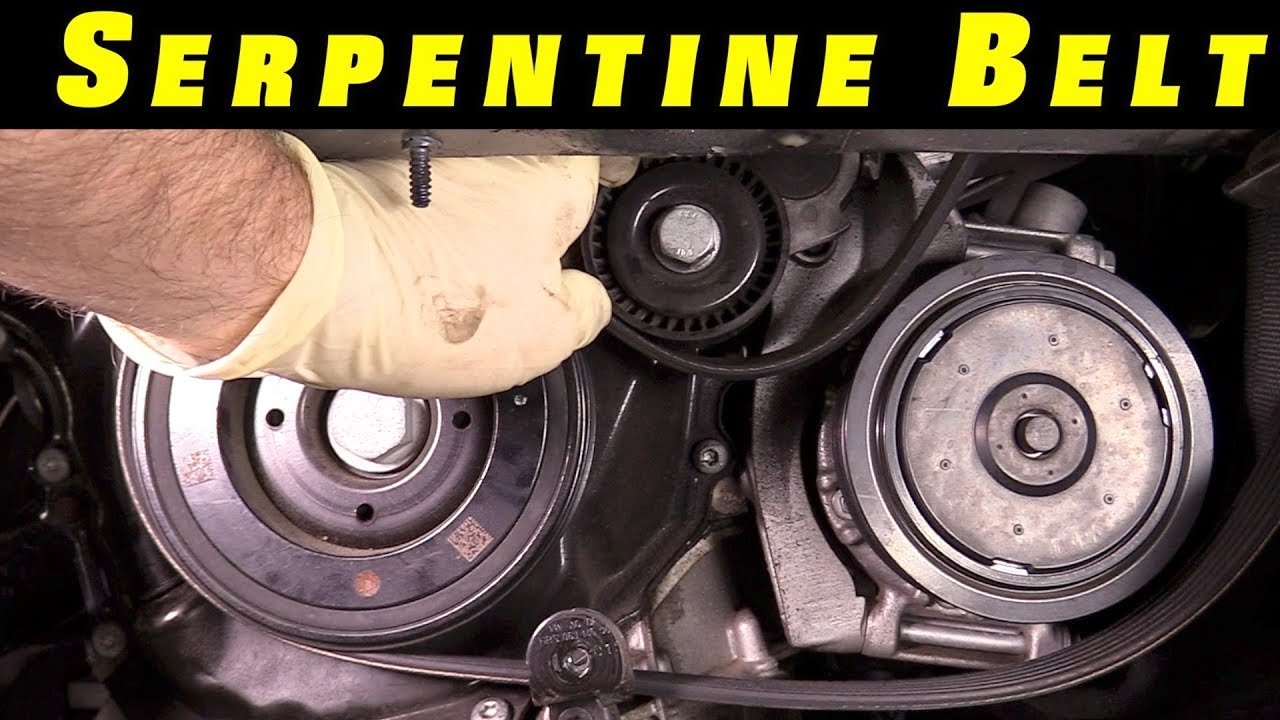

Use the belt tensioner tool or a ratchet to relieve tension on the serpentine belt. Rotate the tensioner arm to loosen the belt.

4. Remove the Old Belt

Once the tension is released, carefully remove the old serpentine belt from the pulleys.

5. Install the New Serpentine Belt

Refer to the serpentine belt routing diagram and install the new belt around the pulleys, ensuring it is seated properly.

6. Reapply Tension

Use the belt tensioner tool to apply tension to the new belt, ensuring it is tight and secure.

7. Inspect and Test

Double-check the belt routing and inspect for any loose fittings. Start the engine and listen for any unusual noises.

Common Mistakes to Avoid

Avoid these common mistakes when replacing your serpentine belt:

- Not following the routing diagram

- Forgetting to check the tensioner and pulleys for wear

- Using the wrong size belt

- Neglecting to inspect other components driven by the belt

Maintenance Tips for Serpentine Belts

To prolong the life of your serpentine belt, consider these maintenance tips:

- Regularly inspect the belt for signs of wear.

- Keep the engine area clean and free of debris.

- Replace the belt according to the manufacturer's recommended schedule.

- Ensure the belt tensioner is functioning correctly.

Conclusion

Replacing the serpentine belt is an essential part of vehicle maintenance that can prevent significant issues down the road. By recognizing the signs of wear, gathering the right tools, and following the step-by-step process outlined in this guide, you can successfully replace your serpentine belt and keep your vehicle running smoothly. Don't hesitate to leave a comment or share this article if you found it helpful!

Remember, regular maintenance not only extends the life of your vehicle but also ensures your safety on the road. Stay informed, stay proactive, and your vehicle will thank you!

You Might Also Like

Bachelorette Party Ideas: Unforgettable Ways To Celebrate Your Last Night Of FreedomHow To Patent An Idea: A Comprehensive Guide

Understanding Beer Belly: Causes, Effects, And Solutions

Discovering The Best Argentine Food Near Me: A Culinary Journey

Why Are My Brakes Squeaking? Understanding The Causes And Solutions

Article Recommendations

- Cast Of Hidden Figures

- Galaxy Playdough

- Jeremy Wariner Net Worth

- Daryl Hannah

- Corinne Foxx

- Future Opportunities_0.xml

- Madison Beer Nude Leak

- Mia Hamm Soccer Player

- Girl Meets World Cast

- Claudine Blanchard Crimes