Crankshaft counterweight plays a crucial role in the functioning of internal combustion engines, significantly influencing engine performance and longevity. In this comprehensive article, we will delve into the intricate details of crankshaft counterweights, exploring their design, purpose, and the impact they have on engine dynamics. With an emphasis on expertise, authoritativeness, and trustworthiness, we aim to provide you with an in-depth understanding of this essential engine component.

The crankshaft is a key element in converting linear motion into rotational motion, and the incorporation of counterweights is vital for maintaining balance within the engine. Through careful engineering and design, crankshaft counterweights help manage vibrations and improve overall performance. In the following sections, we will break down the various aspects of crankshaft counterweights, including their types, materials, and how they contribute to engine efficiency.

By the end of this article, you will gain valuable insights into the significance of crankshaft counterweights and how they impact the overall operation of an engine. Whether you are an automotive enthusiast, a student of mechanical engineering, or simply someone interested in understanding engine mechanics, this article promises to deliver a wealth of knowledge on the subject.

Table of Contents

- What is Crankshaft Counterweight?

- Importance of Counterweights in Engine Performance

- Types of Crankshaft Counterweights

- Design and Materials of Counterweights

- Counterweight Calculation and Balancing

- Impact of Counterweights on Engine Efficiency

- Common Issues and Troubleshooting

- Future Trends in Crankshaft Counterweight Design

What is Crankshaft Counterweight?

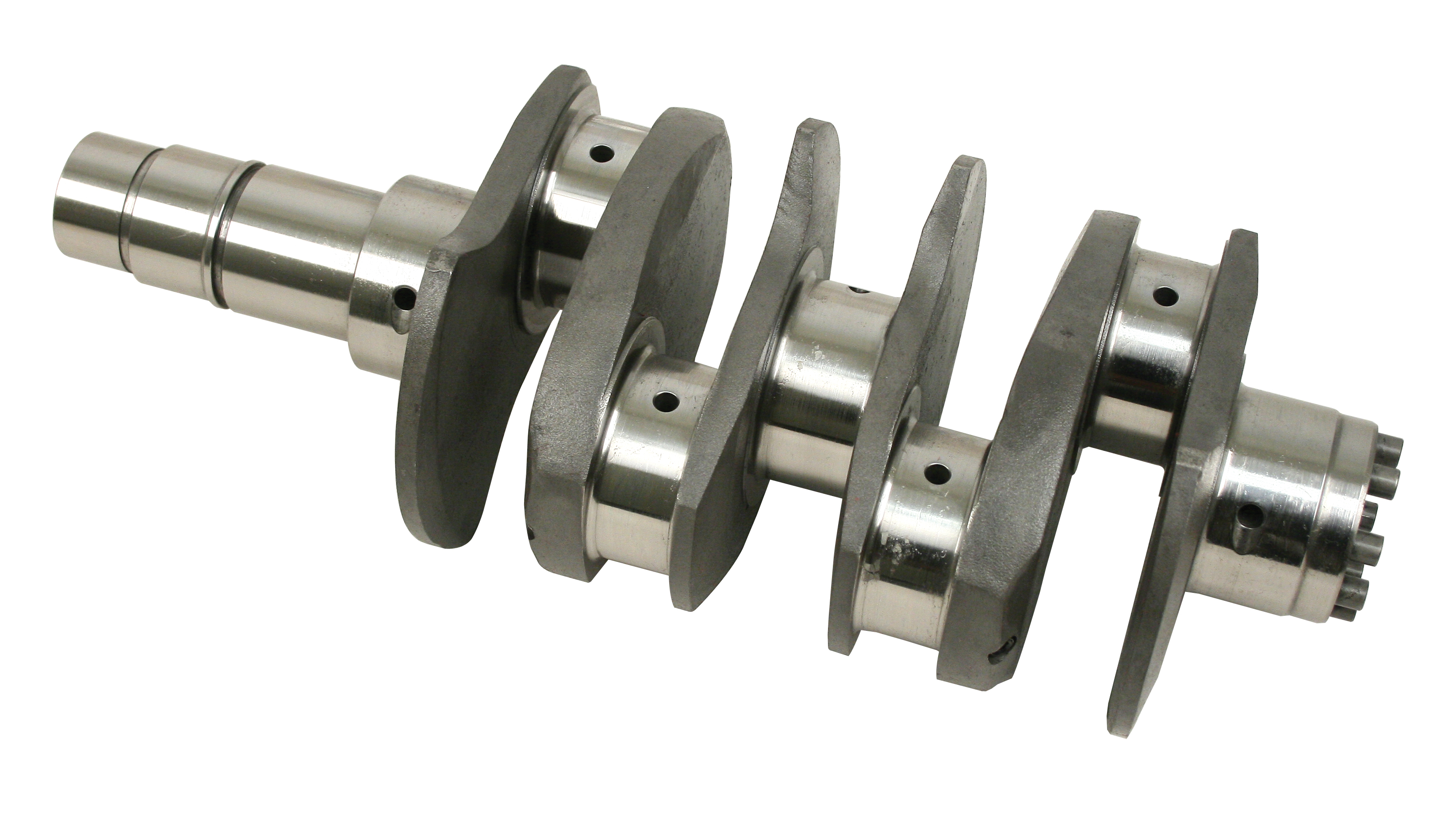

Crankshaft counterweights are protrusions or weights attached to the crankshaft to balance the rotational forces created during engine operation. They serve the primary purpose of counteracting the inertial forces generated by the reciprocating components, such as pistons and connecting rods. This balancing act is essential for reducing vibrations and ensuring smoother engine operation.

In simple terms, when the crankshaft rotates, various forces act upon it, potentially leading to vibrations and instability. Counterweights, by offsetting these forces, help maintain balance and prevent excessive wear and tear on engine components.

Importance of Counterweights in Engine Performance

The significance of crankshaft counterweights cannot be overstated. Here are some key reasons why they are essential for optimal engine performance:

- Vibration Reduction: Counterweights minimize vibrations caused by the reciprocating motion of the pistons, leading to a smoother operation.

- Engine Longevity: By reducing vibrations, counterweights help prolong the life of engine components, minimizing the risk of premature failure.

- Improved Efficiency: A well-balanced crankshaft leads to better fuel efficiency, as the engine operates more smoothly and requires less energy to perform.

- Enhanced Performance: Counterweights contribute to improved throttle response and overall engine performance, providing a more enjoyable driving experience.

Types of Crankshaft Counterweights

Crankshaft counterweights can be classified into several types based on their design and application:

1. Static Counterweights

Static counterweights are fixed weights installed on the crankshaft to balance the engine. They are commonly found in most standard engines and are designed based on the specific weight distribution of the engine components.

2. Dynamic Counterweights

Dynamic counterweights, on the other hand, can change position or weight distribution based on engine speed and load. These are often used in high-performance or racing engines to adapt to varying conditions.

3. Adjustable Counterweights

Adjustable counterweights allow for fine-tuning of the engine balance and can be modified to suit specific performance requirements or preferences.

Design and Materials of Counterweights

The design of crankshaft counterweights is critical for their effectiveness. Key considerations include:

- Weight Distribution: Proper weight distribution is essential for achieving the desired balance and minimizing vibrations.

- Shape and Size: The shape and size of the counterweights are designed to optimize their performance based on engine specifications.

- Materials: Common materials for counterweights include cast iron, steel, and aluminum, each offering different benefits in terms of weight, durability, and cost.

Counterweight Calculation and Balancing

Calculating the appropriate counterweight is a crucial step in engine design. Engineers must consider factors such as:

- Engine Configuration: The type of engine (inline, V-shaped, etc.) affects the required counterweight design.

- Piston Weight: Heavier pistons may require larger counterweights to maintain balance.

- RPM Range: The engine's operating RPM range influences counterweight selection to ensure stability at different speeds.

Impact of Counterweights on Engine Efficiency

Crankshaft counterweights play a significant role in enhancing engine efficiency. Their ability to minimize vibrations contributes to:

- Reduced Friction: Less vibration means reduced friction between moving parts, leading to lower energy consumption.

- Improved Power Delivery: A balanced crankshaft ensures that power is delivered more efficiently to the wheels, enhancing overall performance.

- Fuel Economy: A smoother running engine consumes fuel more efficiently, contributing to better fuel economy.

Common Issues and Troubleshooting

Despite their importance, crankshaft counterweights can experience issues that may affect engine performance. Common problems include:

- Worn Bearings: Excessive wear on bearings can lead to imbalance and vibrations.

- Improper Installation: Incorrectly installed counterweights can cause misalignment and increased vibrations.

- Material Fatigue: Over time, the materials used for counterweights may experience fatigue, leading to failure.

Future Trends in Crankshaft Counterweight Design

The automotive industry is continually evolving, and so are the designs of crankshaft counterweights. Future trends may include:

- Use of Advanced Materials: The exploration of lightweight and durable materials to reduce overall engine weight while maintaining strength.

- Smart Counterweights: Integration of sensors and technology to monitor and adjust counterweights in real-time based on engine conditions.

- 3D Printing: The adoption of 3D printing technology for custom counterweight designs tailored to specific engine needs.

Conclusion

In conclusion, crankshaft counterweights are indispensable for the efficient operation of internal combustion engines. They play a vital role in reducing vibrations, improving performance, and extending engine life. Understanding their design, importance, and impact on engine dynamics can help automotive enthusiasts and professionals alike appreciate the intricacies of engine mechanics.

We encourage you to leave your thoughts in the comments section below and share this article with fellow automotive enthusiasts. For more insightful articles on engine technology and performance, be sure to explore our website.

Penutup

Thank you for taking the time to read this article on crankshaft counterweights. We hope you found it informative and engaging. Stay tuned for more content that delves into the fascinating world of automotive engineering!

You Might Also Like

Une Plante Qui Vit Dans L'Eau Sans Substrat: Exploring Aquatic Plants And Their Unique AdaptationsAre Doves Violent? Understanding The Nature Of These Peaceful Birds

History Of Panama City, Florida: A Journey Through Time

How Often Do Landlords Have To Paint: A Comprehensive Guide

8 Year Old Birthday Party Ideas For Boys: Creative And Fun Ways To Celebrate

Article Recommendations

- Whats Akons Real Name

- Ubuntu Install Deb File Command Line

- Lolo Soetero

- Hasselblad 553 Elx

- Karol G Tour

- Lori Woodley

- Best Bbq In Denver

- April Cancer Horoscope 2024

- Toy Robot Dogs

- Best Exercise Classes